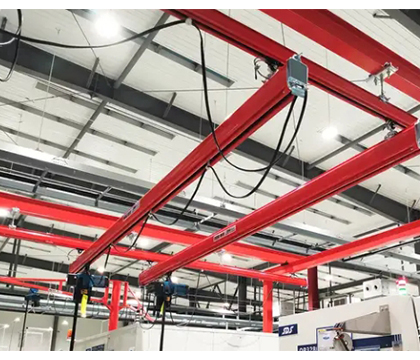

The KBK light crane system is a flexible lifting solution suitable for industrial assemly lines, workshop material handling, warehousing and logistics and other applications. Through the combination of standardized modules, it can meet the customized needs under different working conditions. The KBK light crane system has been widely used in modern industrial production due to its advantages such as easy installation, light structure and flexible operation.

KBK Light Crane Components

1. KBK track

KBK track is the basis of the entire suspension crane system. It can be flexibly combined to meet the diverse track layout. The design of the track takes into account the load-bearing capacity and docking accuracy to ensure the stable operation of the entire system.

2. Suspension system

The suspension device is an important part of connecting the KBK track and the factory structure. The use of spherical hinge suspension ensures the horizontal and vertical adjustment flexibility of the system, while effectively reducing structural stress.

3. Buffer end pad

The end buffer pad is situated at the end of the track and the main beam. Its primary purpose is to reduce the impact from collisions and safeguard the track and transported materials.

4. Cable slider

The cable slider is designed for the power supply of the KBK light crane system. It can slide smoothly when the system is running to ensure the continuous supply of power.

5. Traveling trolley

The walking trolley is equipped with nylon wheels and supported by rolling bearings, making manual operation easy. Their wear resistance and low noise characteristics not only improve work efficiency, but also create a good working environment.

6. Trolley connector

The trolley connector is used to connect multiple trolleys to enhance the system's carrying capacity and make the system run more smoothly.

7. Travel drive

The travel drive component uses the friction drive principle to drive the trolley on the track through the operation of the traction motor.

8. Electric hoist

As the core lifting component of the KBK system, the electric hoist has a compact design that reduces the space occupation of the system and realizes efficient material handling through remote control operation.

Application of KBK Light Crane System

1. Assembly line material handling

The KBK suspension crane system provides an efficient solution for material handling in the assembly line, making the production process more coherent and improving assembly efficiency.

2. Workshop space utilization

Due to the flexibility and modularity of the KBK light crane system, it can be customized according to the specific space of the workshop and make full use of the three-dimensional space of the workshop.

3. Warehouse logistics

In the field of warehouse logistics, the light crane system can improve the speed and accuracy of goods storage and retrieval, simplify the logistics process, and reduce labor intensity.

KBK Light Crane System Advantages

1. Flexibility

The modular design of the KBK system allows it to be quickly combined and adjusted according to specific application requirements.

2. Easy to Expand

As production requirements evolve, the light crane system can be easily expanded or modified to suit new working conditions.

3. Economical

The KBK system offers the advantage of low installation and maintenance costs, and its lightweight structure means that there are relatively low requirements for on-site building structures.

The KBK light crane system plays an important role in modern industry with its high flexibility, reliability and economy. Through standardized modular components, it can not only meet diverse production needs, but also bring higher work efficiency and better economic benefits to enterprises. With the continuous advancement of technology, the KBK system will undoubtedly continue to occupy an important position in the field of material handling and automated production.