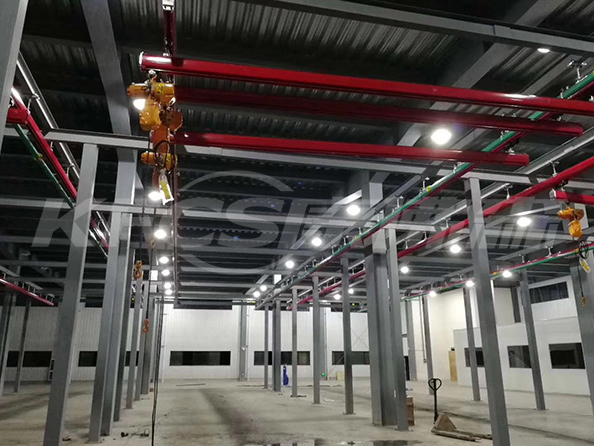

1t light crane self-supporting crane, 1 ton rigid rail light crane, combined self-supporting crane

Lifting weight up to 2000kg, multiple track models and spans, prefabricated standard modular design makes expansion and relocation easier

Closed rail design can effectively reduce contamination and dust

Rigid fixed rail, load positioning

The steel rail formed by cold rolling has light weight, high accuracy and smooth rolling surface, which effectively reduces the resistance of trolley rollers

Wide application range, suitable for material handling environment

For a single work unit, the cost is low and economical

Easy to install, reducing installation time and cost

Increased operator satisfaction

Realize a safe operating environment

Effectively improve production efficiency and meet rapid return on investment

The combined beam self-supporting crane can complete the arduous overhead lifting task and can undertake the frequent overhead material transportation work;

It can be installed on an ordinary 15cm thick reinforced concrete floor without putting pressure on the roof structure of the building. It uses a prefabricated standard modular design structure, which can be easily expanded with the expansion of the work unit;

Easy to install, easy to move and install;

The combined self-supporting crane is made of steel, with a lifting weight between 75kg and 2000kg, and the total length of the main girder is 10m (aluminum main girder is optional);

Compared with traditional beam cranes, Kunfeng Heavy Industry's closed rail design makes the handling force required to be 1/3 of that of traditional beam cranes;

The truss rail design makes the span larger and the installation layout more flexible.

Lifting weight up to 2000kg, multiple track models and spans, prefabricated standard modular design makes expansion and relocation easier

Closed rail design can effectively reduce contamination and dust

Rigid fixed rail, load positioning

The steel rail formed by cold rolling has light weight, high accuracy and smooth rolling surface, which effectively reduces the resistance of trolley rollers

Wide application range, suitable for material handling environment

For a single work unit, the cost is low and economical

Easy to install, reducing installation time and cost

Increased operator satisfaction

Realize a safe operating environment

Effectively improve production efficiency and meet rapid return on investment

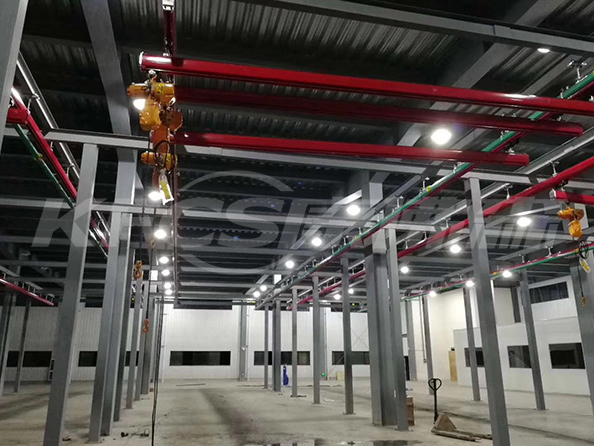

The combined beam self-supporting crane can complete the arduous overhead lifting task and can undertake the frequent overhead material transportation work;

It can be installed on an ordinary 15cm thick reinforced concrete floor without putting pressure on the roof structure of the building. It uses a prefabricated standard modular design structure, which can be easily expanded with the expansion of the work unit;

Easy to install, easy to move and install;

The combined self-supporting crane is made of steel, with a lifting weight between 75kg and 2000kg, and the total length of the main girder is 10m (aluminum main girder is optional);

Compared with traditional beam cranes, Kunfeng Heavy Industry's closed rail design makes the handling force required to be 1/3 of that of traditional beam cranes;

The truss rail design makes the span larger and the installation layout more flexible.

Lifting weight up to 2000kg, multiple track models and spans, prefabricated standard modular design makes expansion and relocation easier

Closed rail design can effectively reduce contamination and dust

Rigid fixed rail, load positioning

The steel rail formed by cold rolling has light weight, high accuracy and smooth rolling surface, which effectively reduces the resistance of trolley rollers

Wide application range, suitable for material handling environment

For a single work unit, the cost is low and economical

Easy to install, reducing installation time and cost

Increased operator satisfaction

Realize a safe operating environment

Effectively improve production efficiency and meet rapid return on investment

The combined beam self-supporting crane can complete the arduous overhead lifting task and can undertake the frequent overhead material transportation work;

It can be installed on an ordinary 15cm thick reinforced concrete floor without putting pressure on the roof structure of the building. It uses a prefabricated standard modular design structure, which can be easily expanded with the expansion of the work unit;

Easy to install, easy to move and install;

The combined self-supporting crane is made of steel, with a lifting weight between 75kg and 2000kg, and the total length of the main girder is 10m (aluminum main girder is optional);

Compared with traditional beam cranes, Kunfeng Heavy Industry's closed rail design makes the handling force required to be 1/3 of that of traditional beam cranes;

The truss rail design makes the span larger and the installation layout more flexible.

Lifting weight up to 2000kg, multiple track models and spans, prefabricated standard modular design makes expansion and relocation easier

Closed rail design can effectively reduce contamination and dust

Rigid fixed rail, load positioning

The steel rail formed by cold rolling has light weight, high accuracy and smooth rolling surface, which effectively reduces the resistance of trolley rollers

Wide application range, suitable for material handling environment

For a single work unit, the cost is low and economical

Easy to install, reducing installation time and cost

Increased operator satisfaction

Realize a safe operating environment

Effectively improve production efficiency and meet rapid return on investment

The combined beam self-supporting crane can complete the arduous overhead lifting task and can undertake the frequent overhead material transportation work;

It can be installed on an ordinary 15cm thick reinforced concrete floor without putting pressure on the roof structure of the building. It uses a prefabricated standard modular design structure, which can be easily expanded with the expansion of the work unit;

Easy to install, easy to move and install;

The combined self-supporting crane is made of steel, with a lifting weight between 75kg and 2000kg, and the total length of the main girder is 10m (aluminum main girder is optional);

Compared with traditional beam cranes, Kunfeng Heavy Industry's closed rail design makes the handling force required to be 1/3 of that of traditional beam cranes;

The truss rail design makes the span larger and the installation layout more flexible.