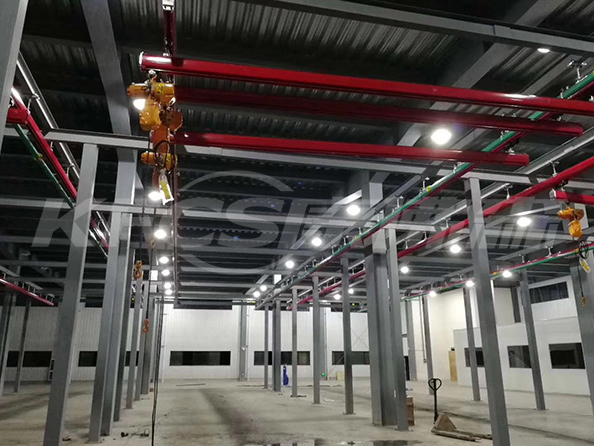

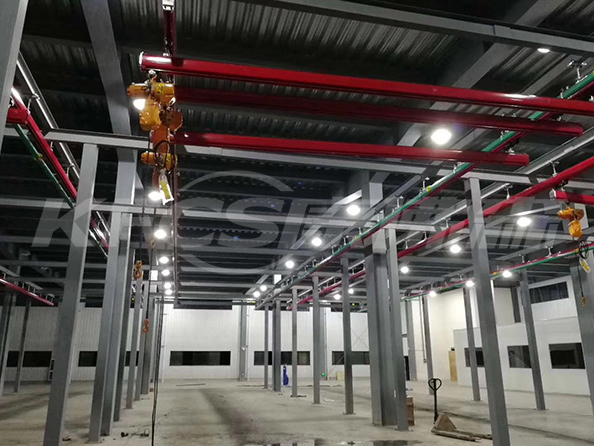

Many people who don’t know about cranes are confused when they hear about kbk cranes. What is kbk? In fact, kbk is a general term for flexible beam cranes, which usually have a lifting capacity of 2 tons, which is a station crane design originating from Europe. kbk is composed of suspension equipment, track, switch, traveling trolley, electric hoist, mobile common electric device (sliding wire) and its control equipment. It only needs to be hung on the roof of the plant or on the beam to keep the raw materials directly transported in the air.

1. The hanger of the combined lifting equipment adopts a rigid overall design, while the hanger structure of the flexible beam system is arranged in a ball and socket shape, which makes the overall style more flexible. However, this kind of flexible design has a great risk of loosening, and it is necessary to improve the maintenance and repair every quarter;

2. The rail of the combined crane is integrated into the rail trolley, which basically eliminates the potential safety hazards of loosening and falling due to long-term use. The rail of the flexible beam system is clamped by a flexible hanger, and a certain period of time is used. There is a high risk of bolt loosening after a while.

The combined crane shows this truss-type track design, which reasonably reduces the total number of lifting points during on-site installation. The distance between each support center is up to 9 meters; the flexible beam system is based on different lifting weights, with an interval of 30 cm to 3 There must be a hanging point in the middle of the meter, which increases the difficulty and time of on-site installation, and the construction regulations for future equipment maintenance and workshop reconstruction are correspondingly higher.

Can be customized accroding to your needs.