Do you know how to check and maintain KBK light cranes?

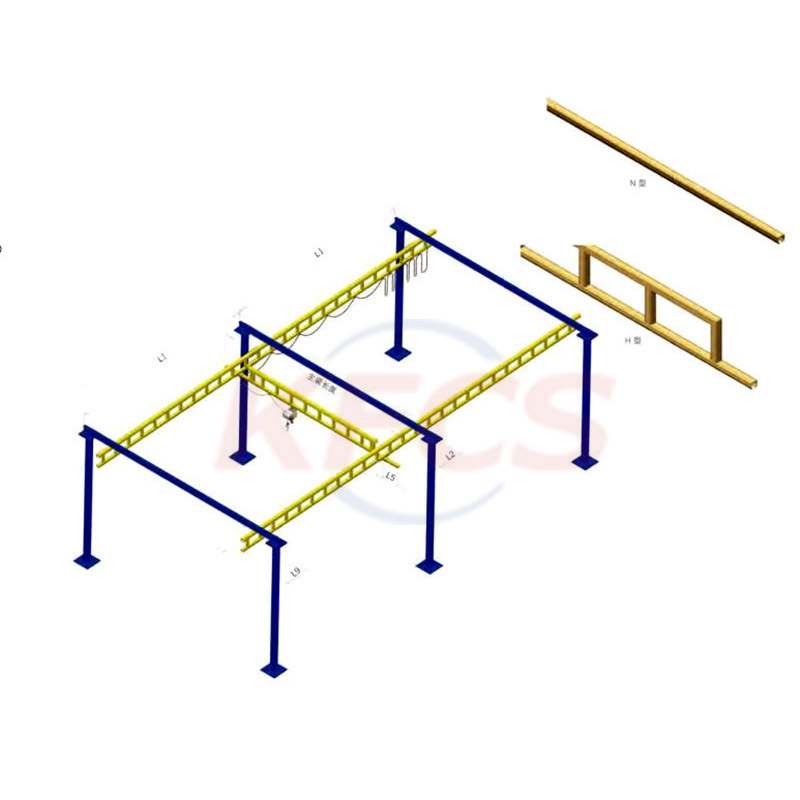

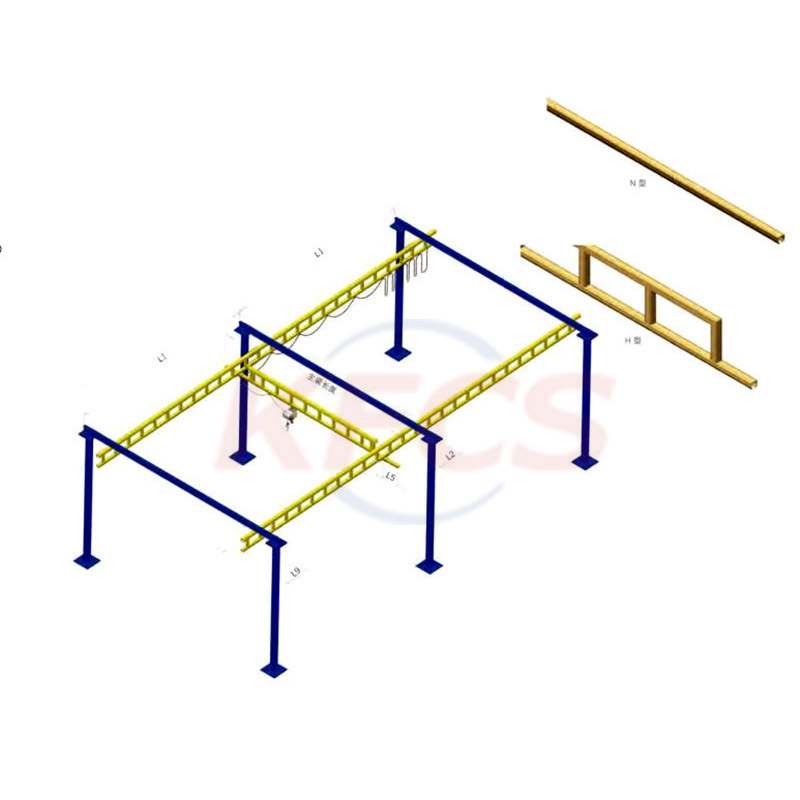

KBK light crane is one of the more common lifting equipment on the market. It is often used in the working environment without any support above the workshop. It is a crane that can run freely suspended above the workshop or workshop. The walking track and span can be set freely. It is an essential lifting equipment for efficient production lines. So what are the inspection and maintenance requirements for KBK light cranes?

1. Check and adjust the pulley, wire rope, hook and winch of the KBK light crane for wear and tear.

2. Check and adjust the uniformity and uniformity of the gap between the brake and the brake wheel of the KBK light crane. To ensure stability and reliability.

3. Check whether the signal lights of KBK light cranes are safe and reliable.

4. Check the transmission oil level and oil quality of the KBK light crane, and add new lubricating oil according to the specified requirements.

5. Check whether the adjustment of the KBK light crane brake is flexible and reliable.

The above is a brief introduction to the inspection and maintenance requirements of KBK light cranes. KBK light cranes are often used in many industrial workshops, warehouses, freight yards and modern industrial production lines for logistics handling operations. Safe and efficient operation has been trusted and supported by the majority of users.

1. Check and adjust the pulley, wire rope, hook and winch of the KBK light crane for wear and tear.

2. Check and adjust the uniformity and uniformity of the gap between the brake and the brake wheel of the KBK light crane. To ensure stability and reliability.

3. Check whether the signal lights of KBK light cranes are safe and reliable.

4. Check the transmission oil level and oil quality of the KBK light crane, and add new lubricating oil according to the specified requirements.

5. Check whether the adjustment of the KBK light crane brake is flexible and reliable.

The above is a brief introduction to the inspection and maintenance requirements of KBK light cranes. KBK light cranes are often used in many industrial workshops, warehouses, freight yards and modern industrial production lines for logistics handling operations. Safe and efficient operation has been trusted and supported by the majority of users.

1. Check and adjust the pulley, wire rope, hook and winch of the KBK light crane for wear and tear.

2. Check and adjust the uniformity and uniformity of the gap between the brake and the brake wheel of the KBK light crane. To ensure stability and reliability.

3. Check whether the signal lights of KBK light cranes are safe and reliable.

4. Check the transmission oil level and oil quality of the KBK light crane, and add new lubricating oil according to the specified requirements.

5. Check whether the adjustment of the KBK light crane brake is flexible and reliable.

The above is a brief introduction to the inspection and maintenance requirements of KBK light cranes. KBK light cranes are often used in many industrial workshops, warehouses, freight yards and modern industrial production lines for logistics handling operations. Safe and efficient operation has been trusted and supported by the majority of users.

1. Check and adjust the pulley, wire rope, hook and winch of the KBK light crane for wear and tear.

2. Check and adjust the uniformity and uniformity of the gap between the brake and the brake wheel of the KBK light crane. To ensure stability and reliability.

3. Check whether the signal lights of KBK light cranes are safe and reliable.

4. Check the transmission oil level and oil quality of the KBK light crane, and add new lubricating oil according to the specified requirements.

5. Check whether the adjustment of the KBK light crane brake is flexible and reliable.

The above is a brief introduction to the inspection and maintenance requirements of KBK light cranes. KBK light cranes are often used in many industrial workshops, warehouses, freight yards and modern industrial production lines for logistics handling operations. Safe and efficient operation has been trusted and supported by the majority of users.