Introduction of kbk track decommissioning

1. Emergency stop. The kbk track constitutes the key equipment of the KBK crane, and its main function is to operate the crane. A track composed of suspension devices, rails, turnouts, sliding vertical lines, and wire rods! If the danger of personal injury or damage to the equipment is found, the emergency stop button should be pressed immediately, and then the power supply of the crane should be cut off (cut; cut off). Emergency stop should also be performed immediately in case of the following failures of the crane: hazards to electrical installations, cables and insulating materials; failure of brakes and safety devices. After the emergency stop of the crane, if the following conditions are met, the equipment can be restarted: the cause of the failure has been eliminated, and the damaged parts have been replaced; the continued operation of the equipment will not cause other hazards.

2. Stop using the crane after get off work. The working strength of the cantilever crane is light. The crane is composed of a column, a rotary arm rotary drive device and an electric hoist. The lower end of the column is fixed on the concrete foundation by anchor bolts, and the cantilever rotation is driven by a cycloidal pinwheel reduction device. The beam runs in a straight line from left to right and lifts heavy objects. Remove the load from the crane and move it to the specified position), lift the hook to the high position and press the emergency stop button to cut off (cut; cut off) the power supply of the crane.

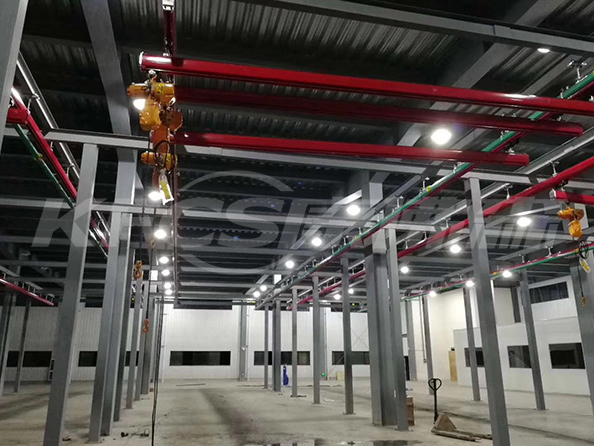

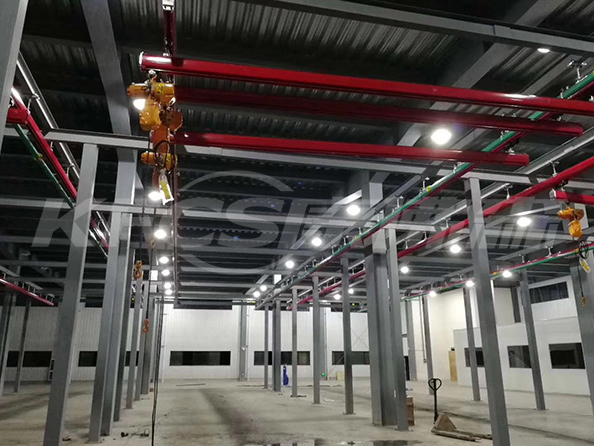

3. KBK track maintenance stops using cranes. The suspension crane can be simply suspended on the building roof or superstructure, and the crane rails do not require additional auxiliary support. Whether it serves part or all of the workshop, it can be installed simply and reliably with low cost. Single-girder suspension cranes are composed of KBK standard components, enabling you to quickly and reliably achieve material transport in specific areas and precise positioning of various components. The maximum lifting weight can reach: 1000kg, and the maximum span can reach: 6m. Remove all loads and additional loads, cut off (cut; cut) the power supply and lock the power switch box with a padlock (lock beam) to prevent unauthorised accidental power supply.