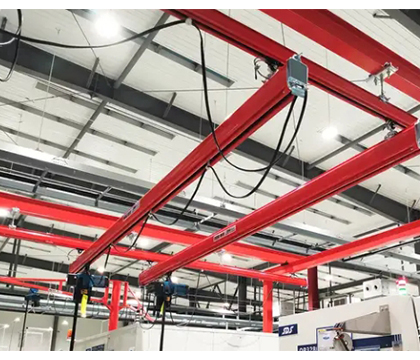

“KBK workstation lifting crane meet the demanding requirements of workplaces and production lines with a lifting capacity of up to 2,000 kg. They are quick to install, can follow tight production schedules, save costs and reduce downtime.”

KBK workstation lifting crane meet the demanding requirements of workplaces and production lines with a lifting capacity of up to 2,000 kg. They are quick to install, can follow tight production schedules, save costs and reduce downtime.

Following are some safety rules and precautions for the operation of KBK crane standard components.

Safe Operation Rules for KBK Cranes

1. KBK crane operators must master the relevant operating specifications related to the use and operation of the crane, and must also be fully trained in the operation and use of the crane.

2. Before the KBK crane starts to use, it should be ensured that the equipment is in a safe and correct operating state.

3. An emergency stop button is installed on the flashlight door. If you find the danger of immediate or possible personal injury or damage to facilities and equipment, you must immediately press the emergency stop button.

Precautions for KBK Crane Use

1. Not allowed to transport people.

2. Not allowed to lift loads above the personnel.

3. Do not handling loads overloaded.

4. It is forbidden to leave the load in the suspended position for a long time without personnel monitoring. At the end of the work, the crane must be unloaded.

5. Move the chain hoist by pulling the load, spreader or carrying hook assembly, rather than pulling the flashlight door.

6. Avoid letting the load drop when the chain is slack to prevent danger and crane damage.

7. Avoid fretting,which refers to avoid jogging the motor quickly and continuously.

KFCS offers custom lifting solution around the world. Professional technical team and after sales service makes customers satisfied. You can ask for a quotation online for the best cleanroom crane that relates to your application. Our excellent technical sales team will work correctly with you to offer the superior hoists and cranes or a custom made solution to meet your specific needs.