Safety rules for the assembly and installation of standard components for KBK cranes

A. Only original parts can be used for the standard components of KBK cranes. Lost parts such as screws, cotter pins, pins and similar objects cannot be replaced.

B. The bolted connection must be tightened, and the bolt fasteners must be replaced after five times of disassembly and assembly; only the appropriate tightening torque can ensure that the bolt fasteners are not loose.

C. Check whether the cotter pin passes through the holes of the boom and the ball bar, only in this way the fasteners will not loosen.

D. When the load is suspended on the cantilever part of the crane, check whether the other end of the crane is tilted.

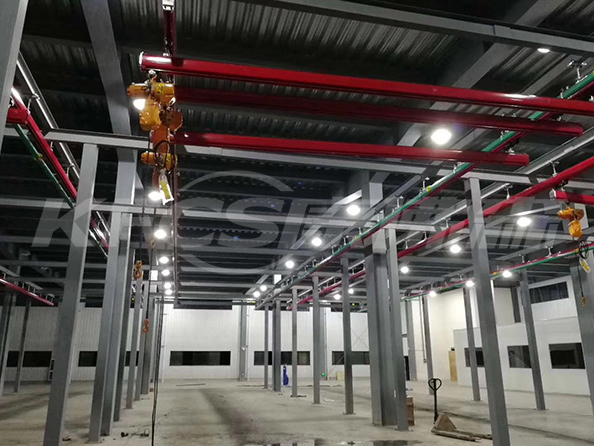

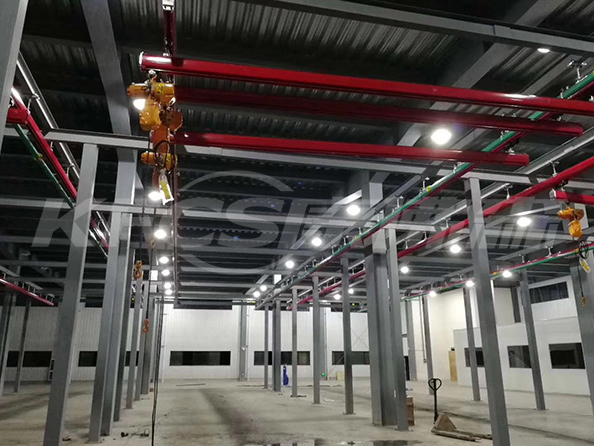

E. There should be enough space around the running rail hanging device for maintenance or free passage.

F. It must be checked after the assembly work is completed; whether the trolley runs smoothly when passing through the track joint; whether the conductor of the trolley line is aligned; whether the contact of the collector is safe and reliable; whether the drag cable runs smoothly; Safe distance between adjacent parts of similar objects.

G. The same number of grounding protection connection points must be provided as the power input and output points. If possible, each connection must be disconnected individually.

H. A power supply connection switch must be provided to connect the power supply to the power line of the KBK crane. It can cut off all phase lines of the crane, and ensure that the switch is placed near the crane and easily accessible. There should be a striking sign.

I. If two or more hoisting devices are powered from the same power source, each device shall be fitted with an isolating switch that allows each hoist to be maintained and repaired individually.