KBK monorail suspension crane is widely used in various workshops and production lines through correct installation and its modular and flexible design, and can operate efficiently and safely.

KBK flexible single beam bridge crane is an indispensable and important equipment in modern production workshops and warehouses. It can not only adapt to a variety of working environments, but also be customized according to customer needs.

KBK aluminum rail workstation crane is suitable for working environments with narrow space or limited height, and is widely used in assembly lines, workshops, warehousing and logistics.

KBK rail can easily realize lifting operation, greatly save manpower and labor, improve work efficiency, increase products and bring more benefits to the enterprise.

KBK suspension cranes are versatile and customizable handing solutions, which is widely used in sectors such as manufacturing, automotive, aerospace.

A portable lifting gantry crane is an indispensable tool in various industrial and construction settings, providing a versatile and efficient solution for heavy lifting tasks.

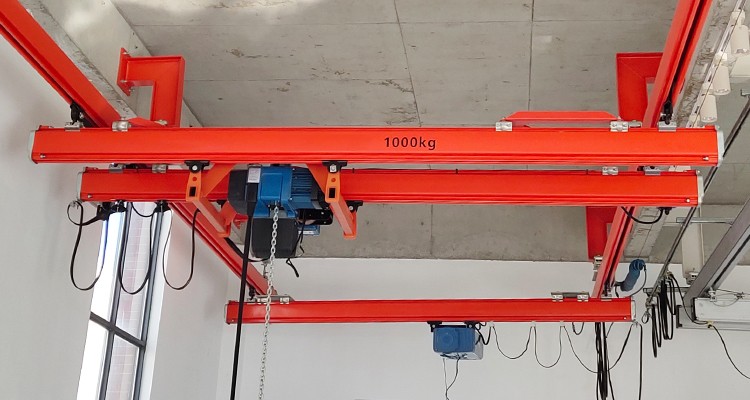

KBK single-girder suspension cranes consist of KBK standard components, which enable you to quickly and reliably realize material transport in specific areas and the positioning of various components.

As a kind of track for hoisting equipment, KBK rails system can effectively ensure the stability of the equipment and has an important impact on the normal and stable operation of the crane. However, KBK rail system has many standards and precautions during installation.

KBK flexible suspension overhead crane manufacturers supply light crane systems, flexible suspension cranes, rigid combination KBK cranes, aluminum alloy track light cranes, etc.

KBK light crane system is a kind of light and small lifting equipment, which is widely used in automatic assembly line workshop. It can easily transport goods from one place to another.