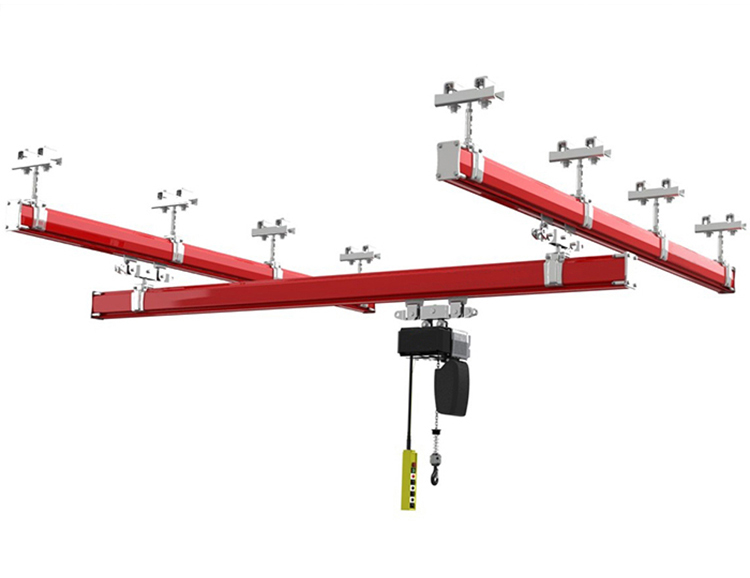

In modern production environments, KBK monorail suspension cranes are widely used in various workshops and production lines due to their modular and flexible design. This type of crane not only improves work efficiency, but also saves valuable space and meets different production needs. In order to ensure that the KBK monorail suspension crane can operate efficiently and safely, correct installation is essential.

The KBK monorail suspension crane runs freely along the track through the hoisting trolley to realize operations such as material handling and hoisting. Due to the flexibility of its design, the KBK monorail suspension crane can adjust the track layout, load capacity, lifting height and other parameters according to specific needs, and is suitable for factory workshops, storage areas and other industrial sites with limited space.

Installation requirements of KBK monorail suspension crane

Site preparation

Before installing the KBK monorail suspension crane, it is necessary to ensure that the site meets the installation conditions. The installation site should be flat and solid, and able to withstand the weight of the equipment and the load during operation. It is necessary to check whether the structure of the ceiling or support beam can support the weight of the track system, especially the load-bearing capacity of the suspension part.

● Space requirements: The installation location should be planned according to the track length and span of the crane and the running path of the hoisting trolley.

● Ceiling or support beams: Make sure that the ceiling or support beams have sufficient load-bearing capacity to support the weight of the crane system.

● Electrical wiring: Before installation, the wiring path of the electrical system needs to be considered to ensure the stability and safety of the power supply.

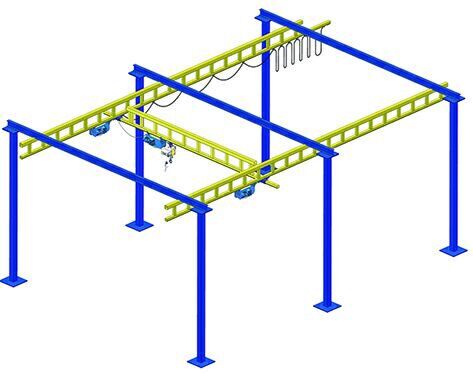

Track installation

The track is one of the core components of the KBK monorail suspension crane. Correct track installation is essential for the smooth operation of the crane. The following points should be noted when installing the track:

● Track flatness: The track should be horizontal or slightly tilted to ensure the smooth operation of the lifting trolley. Any inclination or unevenness will affect the operation effect and safety of the crane.

● Connection and fixation: The connection between the tracks needs to be firm to ensure that there is no looseness. The installation of the fixings must meet the standards to avoid track deviation or uneven force due to loose fixation.

● Track length and curve: The track length can be flexibly adjusted as needed, and the installation of the curved part should ensure the smooth passage of the lifting trolley.

Installation of hoisting trolley and drive system

The installation of hoisting trolley and drive system is an important part of KBK monorail suspension crane. It is necessary to ensure that these parts are firmly installed and operate smoothly:

● Installation of hoisting trolley: The hoisting trolley should slide freely along the track to ensure that there is no jamming. During installation, adjust the position of the hoisting trolley to ensure that it can run smoothly.

● Installation of drive system: The drive system needs to be installed in an appropriate position to ensure that it is well connected with the track and hoisting trolley. Check the connection of the motor and control system to ensure that the electrical part works properly and the line connection is correct.

Installation of electrical system and control system

The installation of the electrical system ensures the normal operation of the KBK monorail suspension crane. The power supply, controller, buttons and other parts need to be strictly installed according to the operation manual:

● Power line: It is necessary to select a suitable power line according to the use environment, and ensure that the electrical connection meets the local electrical safety standards.

● Control system: According to the needs, install a suitable operation panel and control system to ensure that the operator can easily control the start, stop, lifting and other operations of the crane.

● Grounding protection: Ensure that the grounding facilities of the electrical system are complete to avoid safety hazards caused by failures in the electrical system.

Debugging and testing

After installation, equipment debugging and testing are required to ensure the normal operation of all components:

● Trolley operation test: Test the operation of the lifting trolley along the track to ensure that there is no jamming and smooth sliding.

● Electrical system test: Check the wiring of the electrical system and the function of the control system to ensure that the response of operations such as start and stop is normal.

● Safety device inspection: Test the working status of safety systems such as limit switches and overload protection devices to ensure that safety functions are effective.

For more information about the installation service or technical support of KBK monorail cranes, please contact our professional team, and we will provide you with detailed guidance and solutions.