For more than 15 years, KFCS has manufactured crane solution and hoists that have to meet very special requirements in most cases, such as cranes designed and manufactured for cleanroom use. Clean room cranes features smooth surfaces and discreetly integrated components, which improve cleanroom conditions and crane maintenance works.

How much do you know about clean room crane components?

There are two three aspects of clean room crane, hoist, traveling mechanism and lifting mechanism.

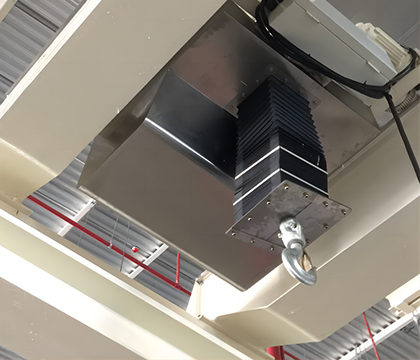

1. Clean Room Hoist

The hoisting mechanism adopts a chain hoist, the chain is not easy to be damaged, and the dust generated by friction is less.

• Hoisting chain: It adopts FEC80 heat-treated alloy steel chain from Japan, which has little wear and long service life. A chain sleeve is installed on the surface to prevent the chain and debris from falling off the hoist.

• Cleanroom hoist is designed with stainless steel sealed housing and nickel-plated hook, which is wear-resistant.

• The double speed lifting mechanism provides precise positioning when using slow speed and efficient loading and unloading when using fast speed, thereby improving overall operational efficiency.

2. Traveling Mechanism of Clean Room Crane

• The trolley wheel adopts 45 forged steel wheel, with nylon wrapping on the outside, and a horizontal nylon guide wheel. There is a 304 stainless steel dust tray under the guide wheel.

• The travel motor adopts the world's best SEW motor, with low noise, high efficiency, and protection level IP54.

• The travel adopts frequency conversion control, stable starting and braking, and obvious energy-saving effect, saving your company's energy consumption.

• An oil accumulation tray is set at the bottom of the reduction box.

3. Crane Structure of Clean Room Crane

A single girder clean room crane is adopted, and the trolley walks at the bottom of the main beam, and the main beam is fully sealed.

• The steel structure adopts Q235B material from standard steel plant, with the shot blasted and painted surface to prevent dust and corrosion.

• Adopted 40*40mm stainless steel square track, clean room cranes are designed with dust plates on both sides to minimize the debris generated by friction. and the wear surface will not rust.

• Stainless steel bars are added to the trolley track to reduce the wear of the trolley wheels, and the wear surface will not rust.

• A tractable sealing device is installed on the main beam to prevent debris from falling, and it can be cleaned regularly.

• Most main beam color of crane is white. At KFCS, the beam color still can be customized.

4. Electrical Part of Clean Room Crane

• The power distribution of crane and hoist adopts safe electric rails, and the collector is equipped with a dustproof plate and no joints to prevent debris from falling.

• Anti-collision limit switches are set between the two cranes, and deceleration device and stop limits are set at the end beams.

• For the operation mode, wireless remote control and pedant control (IP55) are available for clean room crane.

After this article, you must have a full understanding of KFCS clean room cranes. No matter the hoist, trolley, or the crane, reliable team and fabulous clean room cranes are our solutions. Contact us to learn more ergonomic design speciality.